Im thinking if I want to make it as energy efficient as possible a smaller fan with around 5 blades would be best simply because it would allow you to make the blades out of thinner material and thus much lighter. The number of blades would probably be the same type of trade off but just under a smaller area. Also length im assuming would increase airflow along with increasing the area of the flow while costing weight. I mean i understand the angle would determin how much air you push along with the direction so something between 20-45 degrees is probably reasonable. this value corresponds to the natural convection taking place without a cooling fan. I haven't found much as far as getting specific details. We decide not to use one quarter of the model because in this case. I guess its more just figuring out what changing the angle of the blades or the number and length etc would do. So itll probably just be flat simple blades. Yes our goal is actually to build a very simple fan. Use the papers you read as your justification for this choice. Pick the one you think is best and use that to design your fan. Find the difference between swept and straight blade fan profiles and how they compare to radial impeller style fans. If you absolutely Have to design a fan start reading papers on fan blade profile optimization and use them as a starting point. a) Click the arrow below Insert Components and select New Part b) Using Sketch and Features tools, create a lid for each pipe. In this step we will close the geometry on the system by adding lids to the pipes. The optional add-on module for SOLIDWORKS Flow Simulation known as the Electronics Cooling module greatly expands the built-in library of manufacturer’s fan definitions, as well as adding a variety of other useful features for electronics analysis such as enhanced materials for PCBs and IC packages, additional heating models such as two-resistor. Since cost is very likely a factor you are going to end up using an off the shelf fan and you just need to pick the best one. Solidworks Tutorial: Beginner Flow Simulation Tutorial 4) Solidworks will require a closed system to be analyzed. We have been making fans for a few hundred years and you are not going to be able to improve on it in a few month long final design course. Seriously though, don't try and re-invent the wheel.

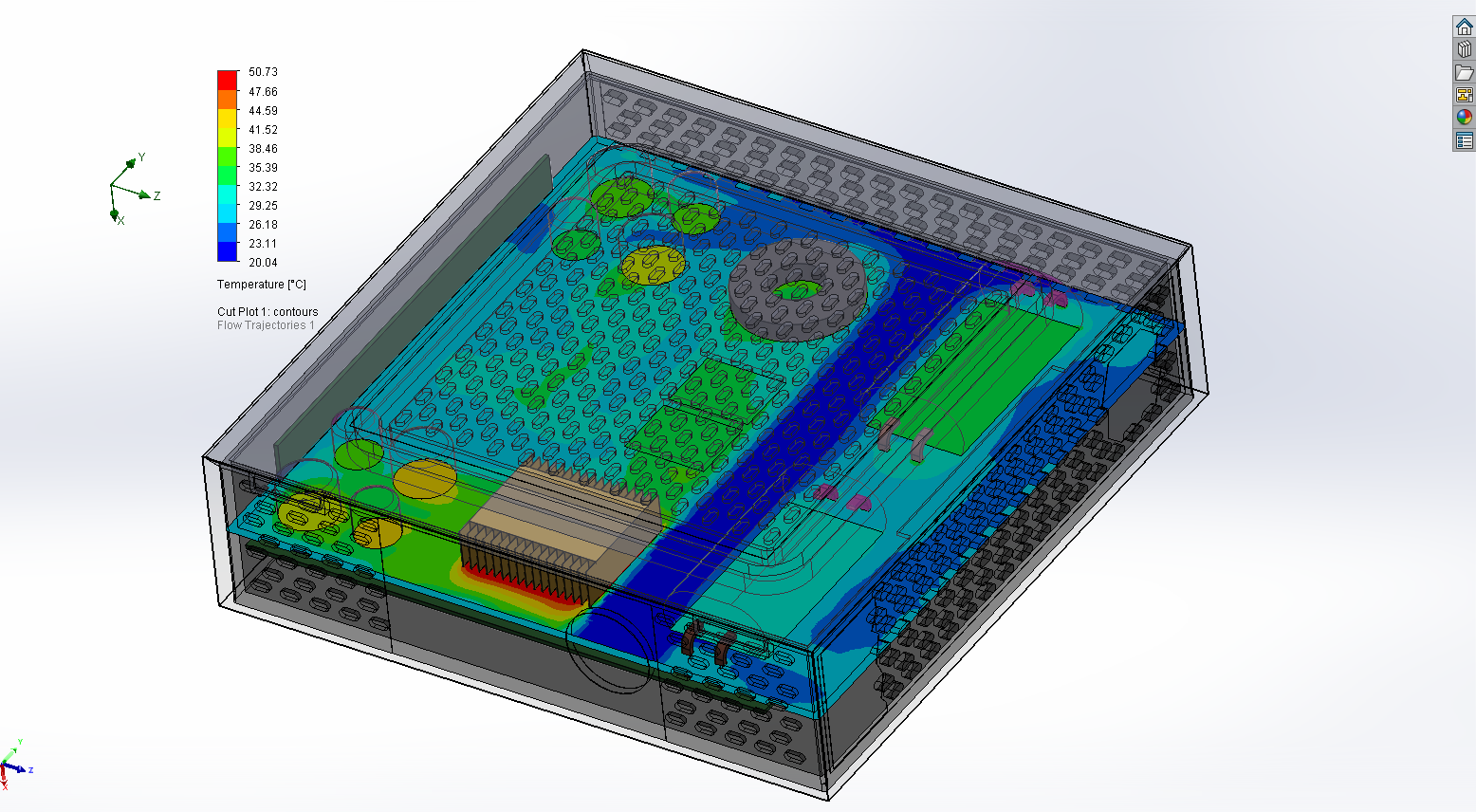

SOLIDWORKS FLOW SIMULATION CLOSED SYSTEM FAN FULL

This is a hyper-simplistic method and neglects several very important things like energy consumption and vortex formation but if you only are capable of doing a full analysis on one profile that would be a good place to start.

Alternatively, as a hack and slash ghetto-tastic solution you could conceivably do it backwards by simulating the airflow you want over a stationary solid fan model and looking for things like wonky pressure gradients.

0 kommentar(er)

0 kommentar(er)